On March 8, 2025, Dr Kuang published a co-authored review paper titled “The road ahead in materials and technologies for volumetric 3D printing” in Nat. Rev. Mater. He collaborated with colleagues around the world to share a perspective on upcoming challenges and research directions in materials design, chemistry, manufacturing techniques, engineering, and convergence with artificial intelligence to move volumetric 3D printing toward widespread industrial and medical applications. The team also highlighted a number of promising applications, including the development of optical and photonic components, rapid prototyping, soft robotics and bioprinting of living cells.

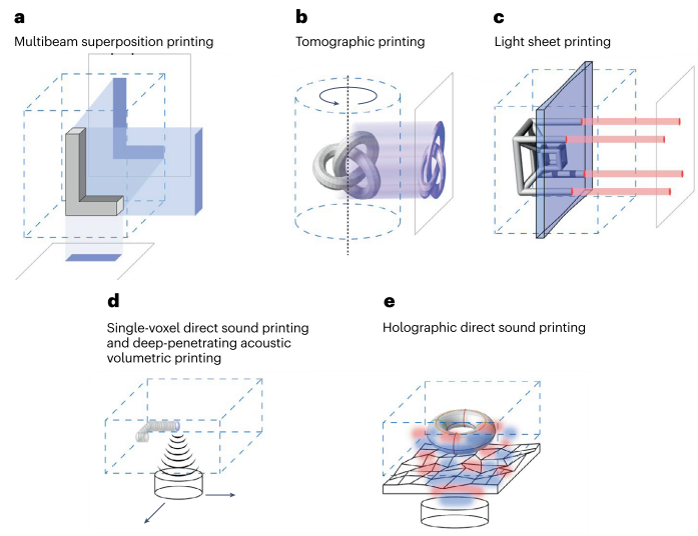

In volumetric 3D printing, complex structures are fabricated directly within a vat of material in response to light and acoustic fields. Unlike conventional 3D-printing methods that use a layer-by-layer fabrication process, volumetric 3D printing can rapidly build structures inside an ink volume in a layerless fashion, providing advantages over conventional methods. Not only is volumetric 3D printing faster, but it also overcomes surface quality issues and is a contactless process, which is important for working with living cells.

For the roadmap, Kuang authored a section discussing developments in acoustic technologies for volumetric 3D printing. It’s a major research focus for Kuang, who has pioneered a technique called deep-penetration acoustic volumetric printing. This technique enables 3D printing of structures inside materials that scatter light—for example, beneath centimeters-thick human tissue. In addition, Kuang also provided his vision on sound-active material design for future ultrasound 3D printing.