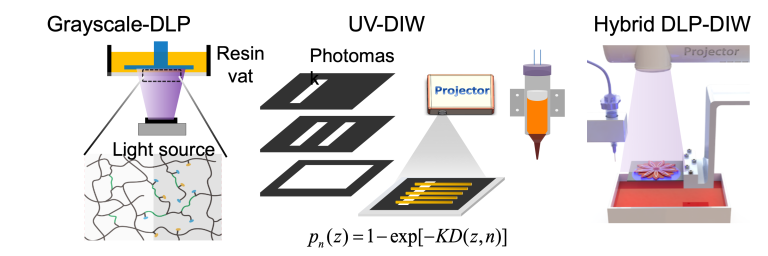

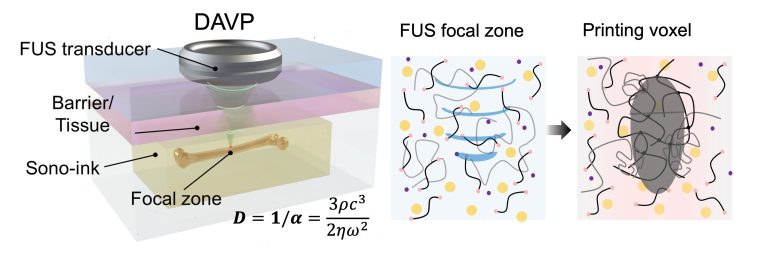

Additive manufacturing (AM, or 3D printing) promises tremendous geometrical freedom for unprecedented structural/functional complexity and material/energy efficiency. We want to answer the question: How to build biomimetic complex constructs with multiscale structure manipulation capability from the macroscale to the molecular level? How to fabricate functional composites with precision voxel-level microstructures and properties control? What are their process-structure-property relationships? How to merge real-time monitoring and adapt printing control for precision and smart manufacturing? We combine novel (bio)polymer ink design, new manufacturing platforms, modeling approaches, and machine learning tools, collectively to develop transformative advanced (de)manufacturing techniques for functional soft materials. For example, we designed novel photo-thermal two-stage curable inks and leveraged the frontal photo-polymerization model to understand the light-mediated polymer network architectures. We developed single-vat grayscale digital light processing (g-DLP) printing, dynamic-photomask-assisted direct ink writing (UV-DIW) printing, and hybrid DLP-DIW printing, to print biomimetic functionally graded materials and multimaterial devices. We also pioneered deep-penetration acoustic volumetric printing (DAVP) using novel self-enhancing sonicated inks and focused ultrasound (FUS) writing techniques. We studied ultrasound-matter interactions of viscoelastic fluids under MHz acoustic waves by experiments and multiphysics modeling to guide the general design of sono-inks for deep penetration, low acoustic streaming, and rapid sono-polymerization for DAVP. We printed sizable composites independent of optical properties without a supporting build platform, even under centimeter-thick tissues.

Deep-penetration acoustic volumetric printing (DAVP) was developed using self-enhancing sono-inks and focused ultrasound (FUS) writing. The understanding of ultrasound-matter interactions by experiments and multiphysics modeling guided the general design of self-enhancing sono-inks with deep penetration, low acoustic streaming, and rapid sono-polymerization. The sono-thermal heating at the FUS focus enables fast and selective material-solidification as the building voxel. Sizable opaque composite hydrogels can be volumetrically printed without a build-platform even through centimeter-thick tissues. (Science, 2023)

Relevant publications (# equal contribution,* corresponding authorship) (Selected)

-

X. Kuang#, Q. Rong#, S. Belal#, Tri Vu, A. Lopez, N. Wang, M. O. Arıcan, M. C. E. Garciamendez-Mijares, M. Chen, J. Yao*, and Y. S. Zhang*, Self-enhancing Sono-inks Enable Deep-Penetrating Acoustic Volumetric Printing. Science, adi1563 (2023)

-

X. Kuang#, J. Wu #, K. Chen, Z. Zhao, Z. Ding, F. Hu, D. Fang, and H. J. Qi*, Grayscale Digital Light Processing 3D printing for Highly Functionally Graded Materials, Sci. Adv. 5, eaav5790 (2019), DOI: 10.1126/sciadv.aav5790.

-

K. Chen#, L. Zhang#, X. Kuang*, V. Li, M. Lei, G. Kang, Z. L. Wang*, and H. J. Qi*, Dynamic Photomask-Assisted Direct Ink Writing Multimaterial for Multilevel Triboelectric Nanogenerator, Adv. Funct. Mater. 0, 1903568 (2019). DOI:10.1002/adfm.201903568.

-

X. Kuang, K. Chen, C. K. Dunn, J. Wu, V. C. Li, and H. J. Qi*, 3D Printing of Highly Stretchable, Shape-Memory and Self-Healing Elastomer toward Novel 4D Printing, ACS Appl. Mater. Interfaces 10, 7381 (2018) DOI: 10.1021/acsami.7b18265.

-

X. Peng#, X. Kuang#, D. J. Roach, Y. Wang, C. M. Hamel, C. Lu, and H. J. Qi*, Integrating Digital Light Processing with Direct Ink Writing for Hybrid 3D Printing of Functional Structures and Devices, Addit. Manuf. 40, 101911 (2021). DOI: DOI: 10.1016/j.addma.2021.101911.