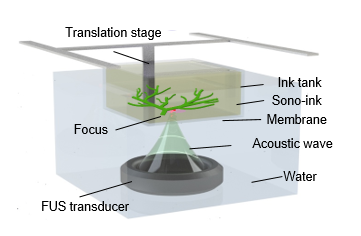

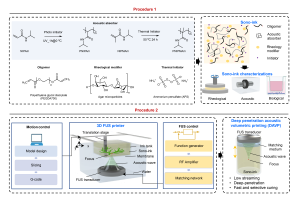

Volumetric printing is an emerging additive manufacturing technique that builds 3D constructs with enhanced printing speed and surface quality by forgoing the stepwise ink renewal. Existing volumetric printing techniques almost exclusively rely on light energy to trigger photopolymerization in transparent inks, limiting the material choice, build size, cell density and in vivo printability. Sonicated ink (or sono-ink) and focused-ultrasound (FUS) writing have been developed for deep-penetration acoustic volumetric printing (DAVP) within optically scattering media and beneath soft tissues. This technology uses rapid sono-thermal heating to induce material solidification at the FUS focal region, constructing 3D objects without the need for a build platform. Here, we describe two procedures necessary to achieve DAVP. First, we provide a step-by-step guide for preparing and characterizing multicomponent viscoelastic self-enhancing sono-inks. The lower critical solution temperature polymers are synthesized as a phase-transition reversible acoustic absorber to formulate the sono-inks. We characterize the rheological, acoustic and cytocompatibility properties of the sono-inks. We then detail the procedure for building a 3D FUS printer by integrating an FUS transducer with a 3D printing platform. The development of the 3D FUS printer needs basic knowledge of the ultrasound system, FUS physics and volumetric printing. Using the sono-inks and the 3D FUS printer, we further provide guidance to evaluate the sono-thermal heating effect and characterize the volumetric printing resolutions. We demonstrate the printing of volumetric constructs through optically scattering materials such as centimeter-thick biological tissues. The procedures require ~470 h to complete.

Key points

- The first procedure covers the preparation and characterizations of multicomponent viscoelastic sono-inks composed of water-soluble acrylate oligomers, a lower critical solution temperature polymer functioning as a reversible acoustic absorber, a rheology modifier and a thermal initiator.

- The second procedure covers the design and implementation of 3D FUS printers and their characterizations including the evaluation of the sono-thermal heating effect, voxel resolution and printing fidelity.

Link: https://www.nature.com/articles/s41596-025-01258-1